Hello future!

Hello future!

We are your ideal partner for the digitalization of your manufacturing company.

Our EVOMECS Software Suite integrates machines, systems and processes completely brand-neutral and location-independent. The result is increasing efficiency along the entire value chain as well as future-proofing your production.

Our mission

End-to-end digitalization in manufacturing

We are an independent software provider for the manufacturing industry and work completely across machines and systems. The EVOMECS Software-Suite integrates all relevant elements of production and digitizes production processes consistently, thereby leveraging significant rationalization potential and significantly improving workplace quality.

We call this Fluid Integration.

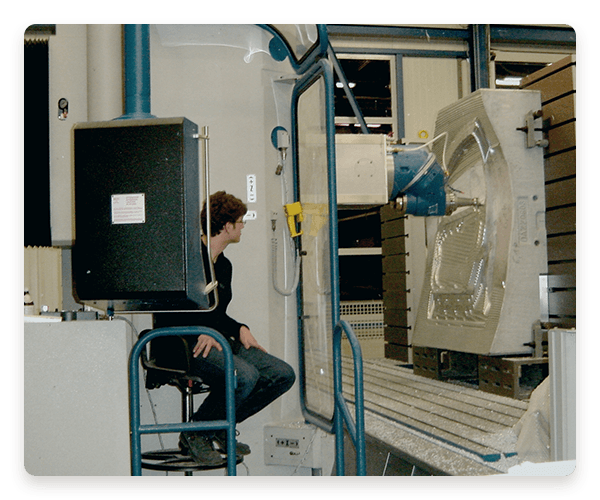

Our roots

Die & mold making

The history of EVOMECS begins in a family-run die and mold making business. This means that we know the challenges of the industry from our own experience and understand exactly what matters.

That's why we develop EVOMECS - to make life easier for you and your employees and to make your business more efficient and future-proof.

Our values

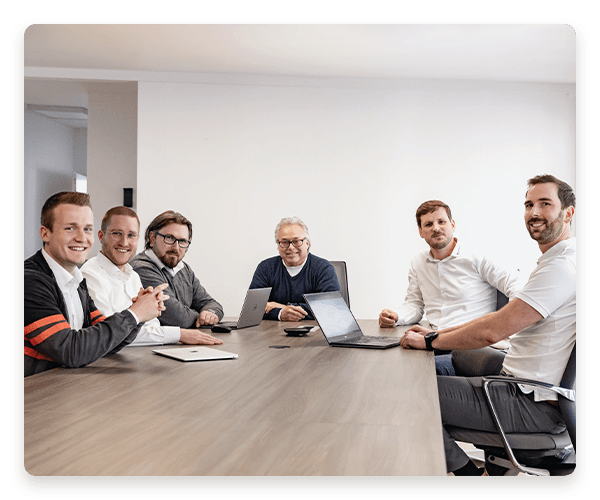

Self-determination, common good & cooperation

SMEs are the economic, social and structural expression of these values. That is why it is our central concern to preserve small and medium-sized enterprises and to work permanently for their continued existence and further development. Our contribution to this is technology that makes people's lives easier.

In the end, every technology is made by people. That's why our pride is not only in our product but above all in our great team that supports each other.

The future lies in holistic connectivity. Within companies, but also across company boundaries.

Dr. Stefan Becker / Managing Partner EVOMECS GmbH

Our vision

Shared Manufacturing

In the future, organizations of all types and sizes will work together transparently, without administration, and in a decentralized and integrated manner in the area of production and trade. Companies can share orders and resources with each other at the touch of a button. Company boundaries will become fluid due to the possibilities of digitization, so that cooperation will be possible to an unprecedented extent. Organizations retain the innovative power and flexibility of the small unit while taking advantage of the benefits of large communities.

Complete networking within companies, but also beyond company boundaries, means a perfectly synchronized interaction of small units to form a larger whole, comparable to a flock of birds.

We are convinced that the future lies in this form of cooperation. This is what we call Shared Manufacturing and for this we are constantly developing EVOMECS.

Horizontal integration

Stable and sustainable

In horizontal integration, resources such as manufacturing machines are made available and shared in a network of partner companies.

In this way, resource fluctuations can be balanced out simply and easily. This creates stability and sustainability.

In horizontal integration, resources such as manufacturing machines are made available and shared in a network of partner companies.

In this way, resource fluctuations can be balanced out simply and easily. This creates stability and sustainability.

Vertical integration

Transparent and safe

In vertical integration, orders are subcontracted and bills of materials are shared at the push of a button.

Workflows and processes mesh seamlessly and in real time, i.e. fluidly. There is complete transparency and security at all times.

In vertical integration, orders are subcontracted and bills of materials are shared at the push of a button.

Workflows and processes mesh seamlessly and in real time, i.e. fluidly. There is complete transparency and security at all times.

Manufacturing clusters & contracting systems

Specialized and efficient

As know-how and resources are shared, specialized and highly efficient manufacturing clusters are created.

In addition, lean and secure procurement systems are created, guaranteeing price certainty and adherence to deadlines in both directions.

As know-how and resources are shared, specialized and highly efficient manufacturing clusters are created.

In addition, lean and secure procurement systems are created, guaranteeing price certainty and adherence to deadlines in both directions.

Are you curious?

We will be happy to show you how you and your production can benefit from our EVOMECS Software Suite during a virtual demo appointment.