Capture machine data automatically

Learning from the past

Record detailed machine data for every job. With the results, you can significantly improve your post-calculation.

Identify the problem

By analyzing your machine data in detail, you can identify previously undiscovered optimization potential.

Become sustainable

Collect high-quality and networked data from your production as a basis for innovative application fields, e.g. in the field of artificial intelligence.

Data quality made by EVOMECS: The use of our software suite creates a database that you can utilize in a large variety of ways.

Map everything in real time

Machine data is captured in real time and can be tracked live.

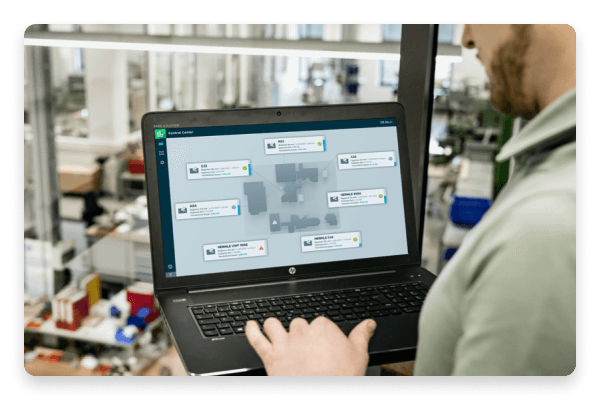

Always keep an eye on the machinery

You can monitor your machines from anywhere via the customizable EVOMECS Control Center.

Monitoring at the push of a button

Directly view the runtime history of individual machines for any time period.

Crack data silos

Export your machine data to your ERP system via the corresponding interface, e.g. for post-calculations.

Our modules are designed to fit into existing system landscapes in the best possible way.

Integrated machine control

- checkHeidenhain TNC 426

- checkHeidenhain iTNC 530

- checkHeidenhain TNC 640

- checkAndron

- checkFanuc

- helpmore on request

We have already integrated the listed systems, devices and machines into EVOMECS in the course of our previous projects. The list is continuously expanding - please feel free to contact us if you have any questions.

EVOMECS means future viability

What potential lies dormant in your production? With our ROI calculator, you can individually calculate the savings potential through the use of the EVOMECS software suite using various scenarios as examples.