Measuring tools automatically

Process reliable measurement

Incorrect entries are excluded. EVOMECS digitally assigns the measurement data from the presetting device to the physical tool.

Simplify work steps

Link. Start measuring process. Data transfer back to EVOMECS. And ready.

Avoid duplicates

Thanks to digital data transmission, redundant or incorrect manual entries are eliminated. Your workers can concentrate on production.

EVOMECS tool management can do more. A major advantage is the integration of the preset process. This ensures data consistency in your production.

Use data end-to-end

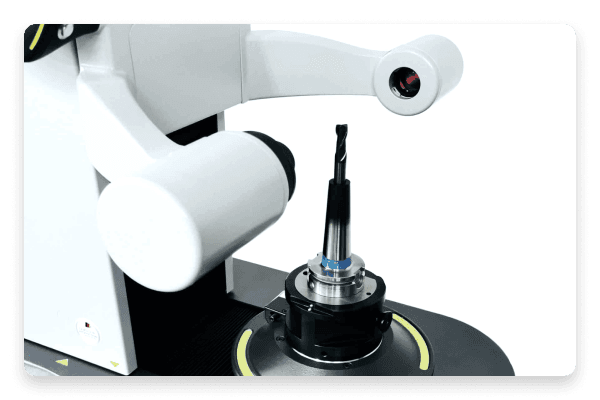

Seamlessly integrate common preset devices of your choice into the EVOMECS system via an interface.

Create measurement templates automatically

Relieve your workers of tedious routine tasks with automatically generated measurement templates for linked tools.

Benefit from comprehensive automation

Another plus: EVOMECS automatically transmits geometry-based tolerance values to the presetting device.

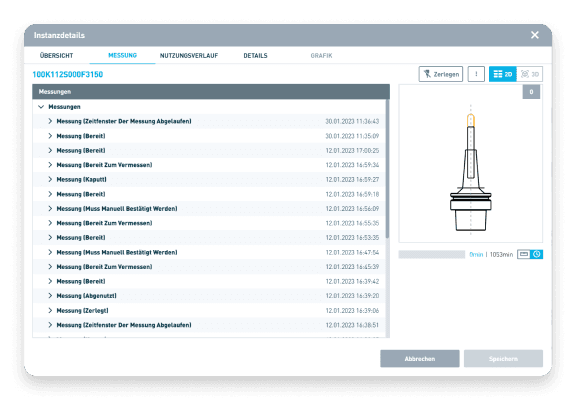

Provide evidence of a complete measurement history

EVOMECS writes a complete measurement history for each physical tool. Thus, all results are still traceable at a later point in time.

Our modules are designed to fit into existing system landscapes in the best possible way.

Integrated presetting devices

- checkZoller

- checkHaimer

- checkHoffmann VG1

- helpmore on request

We have already integrated the listed systems, devices and machines into EVOMECS in the course of our previous projects. The list is continuously expanding - please feel free to contact us if you have any questions.

EVOMECS means future viability

What potential lies dormant in your production? With our ROI calculator, you can individually calculate the savings potential through the use of the EVOMECS software suite using various scenarios as examples.