Electrode process

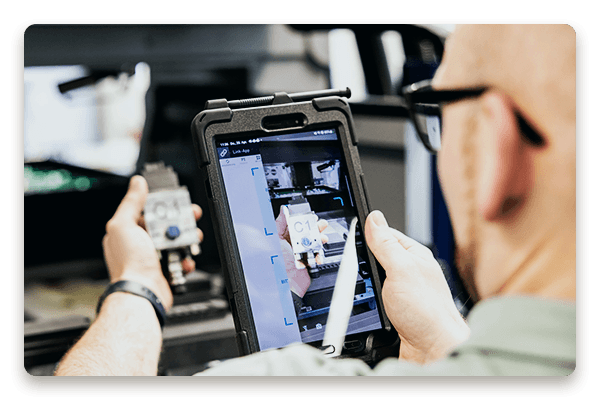

Everything at a glance

With the EVOMECS apps, you have full transparency over your electrodes and the status of the processing.

From people for people

The user-oriented application interface makes production much easier for your employees.

No jerking, no juddering

By using the latest web technologies, the system responds immediately to input, saving valuable time.

Co-creation with experts: we developed the electrode process in partnership with the machine manufacturer OPS-INGERSOLL.

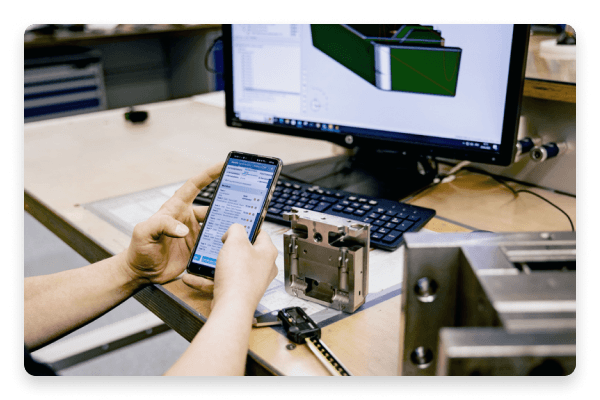

The future is integrated and continuous

Integrate your CAD/CAM system with EVOMECS to lay the foundation for a smooth manufacturing process.

Nothing left to chance

Display electrode reference lists. This way you can plan the optimum sequence of your production.

Think from the end

If the production date of your order is postponed, EVOMECS automatically reprioritizes the production of the electrodes. Thanks to consistent backward planning.

Article, article, article

EVOMECS treats your electrodes as articles. This allows the standardization of electrodes and thus the definition of minimum quantities in the system.

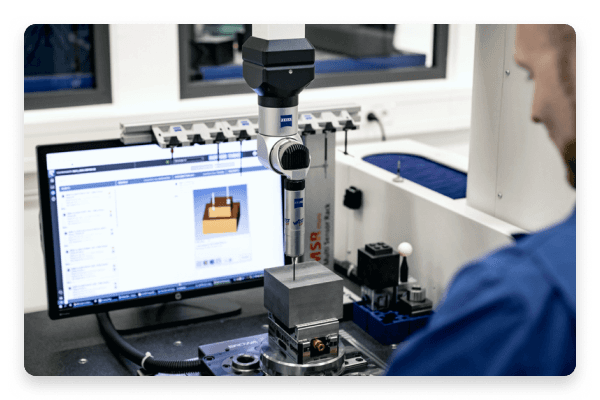

To the point

Transfer the zero offset data of both the electrodes and the workpieces from the measuring machine and store them conveniently in EVOMECS.

Our modules are designed to fit into existing system landscapes in the best possible way.

Integrated CAM systems

- checkTebis

- checkWorkNC

- checkPowerMILL

- checkMastercam

- checkCimatron

- checkPowerspark

- checkhyperMILL

- helpmore on request

Integrated measuring machines

- checkZeiss

- checkDEA

- helpmore on request

Integrated measurement software

- checkZeiss Calypso

- checkZeiss U-Soft

- checkHexagon PC-DMIS

- helpmore on request

We have already integrated the listed systems, devices and machines into EVOMECS in the course of our previous projects. The list is continuously expanding - please feel free to contact us if you have any questions.

EVOMECS means future viability

What potential lies dormant in your production? With our ROI calculator, you can individually calculate the savings potential through the use of the EVOMECS software suite using various scenarios as examples.