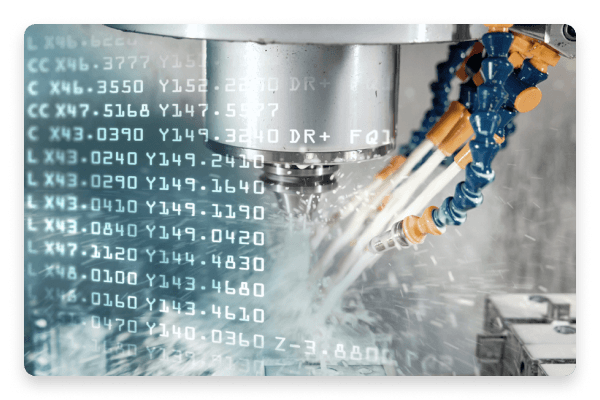

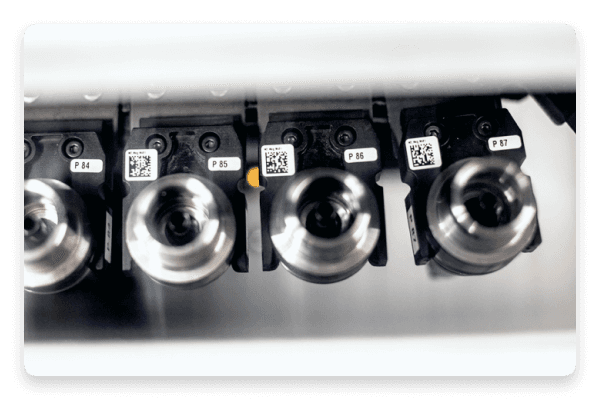

Control CNC machines

Increase efficiency

The processing of the NC code by EVOMECS enables numerous features that provide a significant increase in efficiency.

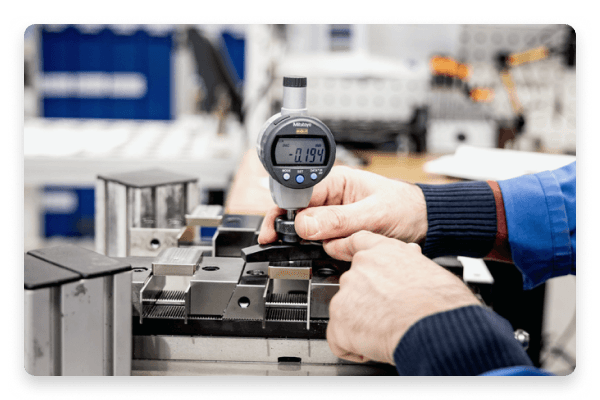

Prevent machine damage

EVOMECS checks the input requirements for starting the machining process and can thus significantly reduce the risk of machine damage.

Enable multi-machine operation

Extensive process automation enables true multi-machine operation and increases employee satisfaction.

Efficiency from start to finish. Your CAM system defines the essential parameters for NC machining right at the start.

If you pick them up in the beginning, you save time at the end.

Offering customers real added value

EVOMECS has its own post-processor suite, which can significantly reduce the number of post-processors used by the customer.

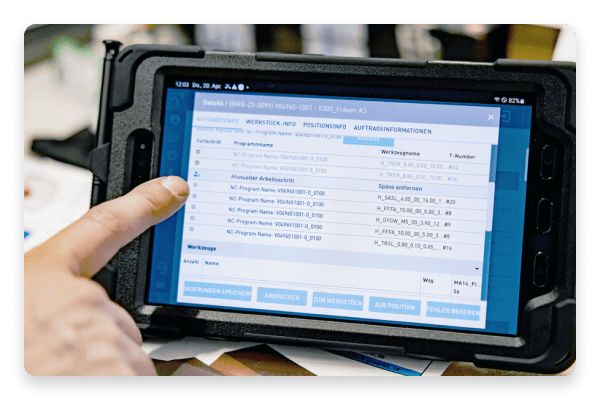

Reduce coordination effort

The CAM programmer can write special commands into the NC program to trigger any manual operations that may be necessary during NC machining.

Trim operation for productivity

Your CAM programmer can declare fits in the part, which the worker can then finalize on the machine without having to touch the NC program again.

Smooth ghost shift

Analyzing the NC program in combination with knowledge of tool life enables true sister tool management.

Our modules are designed to fit into existing system landscapes in the best possible way.

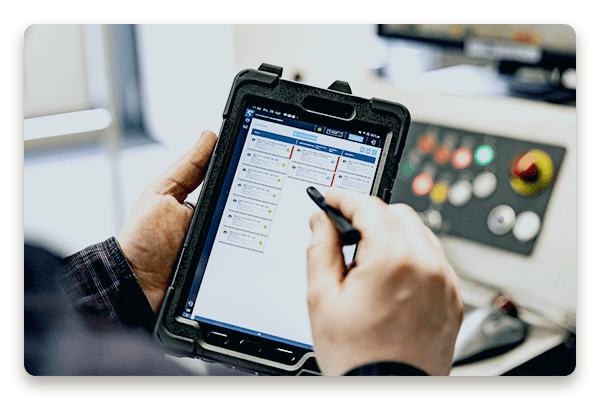

Integrated machine control

- checkHeidenhain TNC 426

- checkHeidenhain iTNC 530

- checkHeidenhain TNC 640

- checkAndron

- checkFanuc

- helpmore on request

We have already integrated the listed systems, devices and machines into EVOMECS in the course of our previous projects. The list is continuously expanding - please feel free to contact us if you have any questions.

EVOMECS means future viability

What potential lies dormant in your production? With our ROI calculator, you can individually calculate the savings potential through the use of the EVOMECS software suite using various scenarios as examples.